Customized Sheet Metal Fabrication

No MOQ Limited

- Start With 1 Piece

- Factory Direct

- Lead Time As Fast As 2 days

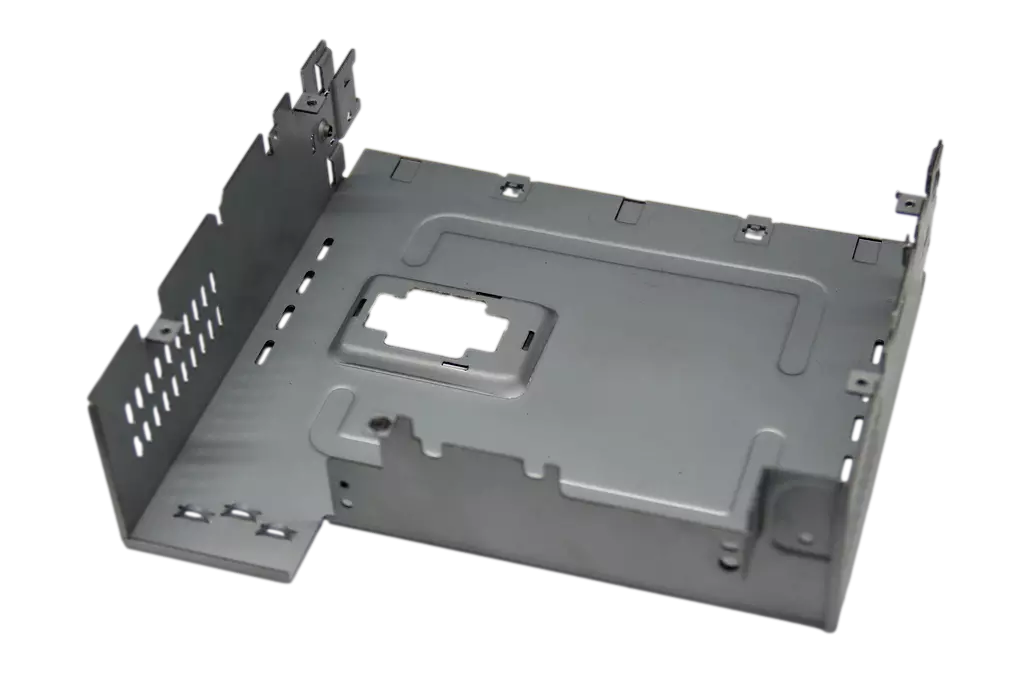

Sheet Metal Fabrication Services

Sheet metal is a metal part machined from uniformly thick and thin sheet metal by cutting, bending, and welding processes. We can often find it in the housing of many pieces of equipment.

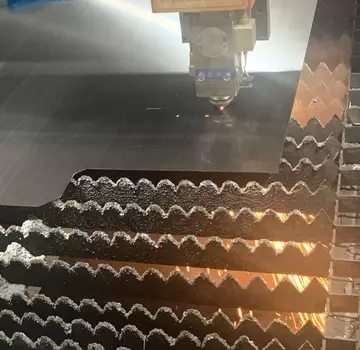

Laser cutting

It is a process that uses a laser beam to cut parts from the metal sheets as per the parts’ profile. Laser cutting is fast and cost-effective in small-quantity runs.

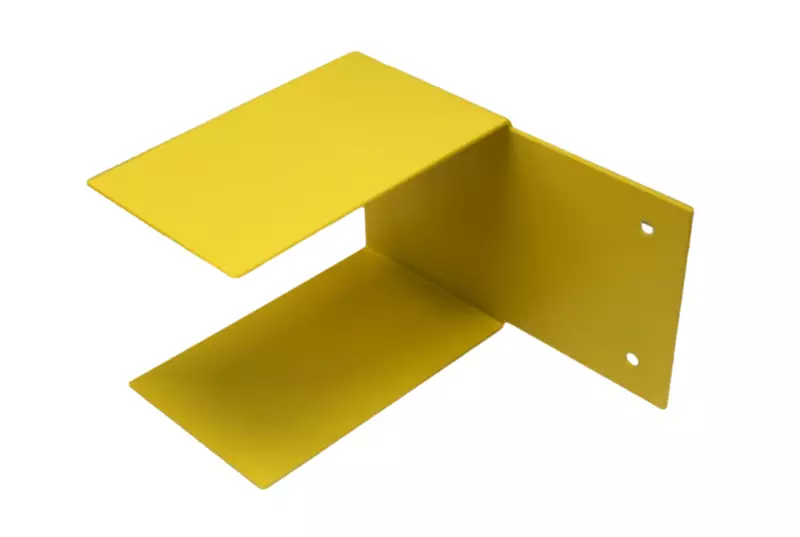

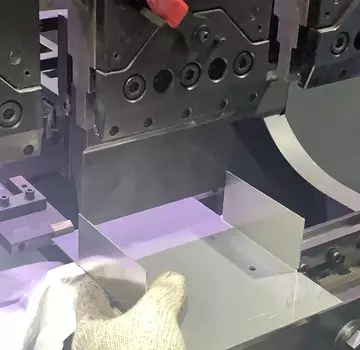

Bending

It uses the ductile properties of the material to create V, U, and channel-bending shapes using molds.

Welding

It helps to achieve complex structures by joining two or more metallic parts together with heat and pressure. However, the parts are easily deformed because of structure.

Riveting

Riveting is using the axial force to press a nail into a metal plate to form a nail head, allowing multiple thin metal plates to be joined without the addition of other components.

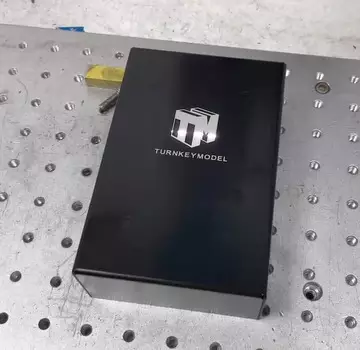

Sheet Metal Fabrication Case Study

The sheet metal team from Turnkey has over 20 years of experience. Rich experience and mature processes ensure the quality of parts. Below is a brief flowchart.

Material

02.02.2023

Mark Chan

Cutting

03.02.~04.02.2023

Daniel Zhou

Bending

05.02~06.02.2023

Andy Sun

Riveting

07.02~08.02.2023

Leo Qian

Welding

09.02.2023

James Zhao

Package

14.02.2023

Leslie Wong

QC

13.02.2023

Ian Xu

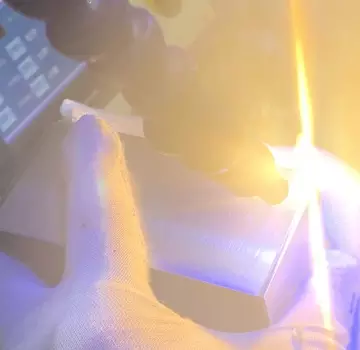

Engraving

13.02.2023

Stone Zhang

Finish

11.02~12.02.2023

Brandon Dong

Grinding

10.02.2023

Bruce Fong

Why Choose Us for Your Sheet Metal Project?

Intelligent Manufacturing Service

Lower risk & cost. DFM report will help you optimize design if necessary

Save communication time & cost. No need to find other partners for different processes

One-stop service. We can support “Design-> Manufacture->Assembly” one-stop delivery

Clear update. You will know every step of your project with detailed photos. No need to worry

Traditional Manufacturing Service

High risk & cost. Without a DFM report in the early stage, problems may occur during the manufacturing

Long communication time & cost. Have to talk with several suppliers for different processes

Single service. May pay extra cost for assembly after collecting the parts from suppliers

Unclear update. You are the last one to know if any delays and have no idea about the delivery schedule

Unstable quality. No clear quality control process and may have problems if any information was not shared

Sheet Metal Fabrication Standards

In order to guarantee the accuracy of the parts and to maintain consistent quality, we generally default to dimensional tolerances for sheet metal parts in accordance with the ISO2768-M standard as below.

Feature | Tolerance |

Bend angle | ±0.5° |

Bend to edge | ±0.2mm |

Edge to edge | ±0.2mm |

Edge to hole | ±0.1mm |

Hole to hole | ±0.1mm |

Hole Diameter | ±0.05mm |

Standard surfaces | Deburring |

Let's Talk About Your Project

Available Materials For Sheet Metal

Here are some normal sheets in our warehouse, if you want any material special, please contact us.

|  |  |  |  |

Aluminum | Steel | Stainless Steel | Copper | Brass |

AL1050, AL1060, AL1100, AL3003, AL5052, AL5754, AL6061, AL7075 | SPCC, SPHC, SGCC, SECC, 1008,1008 Galvanized, 1018, 1018 Galvanized, 1045, 4140, 65Mn | SUS201, SUS301, SUS303, SUS304, SUS316, SUS 430, SUS440C | C101, C110,C1100, T2 | 260, H62, CuSn6 |

Allowable Sheet Thickness

The thickness and thickness tolerance of the sheet will directly affect its manufacturability of the sheet. Below you can find some common sheets in the Chinese market, if they do not meet your expectations, please contact us.

Material | Thickness/mm | Thickness tolerance |

Aluminum | 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9,1.0, 1.2, 1.5, 1.6, 2.0, 2.3, 2.5, 3.0, 3.2, 3.5, 4.0, 5.0, 6.0, 8.0, 10.0, 12.0, 15.0, 20.0 | In general, the tolerance is ±0.1mm for material thickness of less than 3mm. For material thickness of 3-6mm, the tolerance is ±0.15mm. For material thickness greater than 6mm, the tolerance is ±0.5mm. |

Steel | 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.8, 0.9, 1.0, 1.2, 1.5, 1.6, 2.0, 2.3, 2.5, 3.0, 3.2, 4.0, 5.0, 6.0, 8.0, 10.0, 12.0, 16.0, 18.0, 20.0, 25.0 | In general, the tolerance is ±0.1mm for material thickness of less than 3mm. For material thickness of 3-6mm, the tolerance is ±0.15mm. For material thickness greater than 6mm, the tolerance is ±0.5mm. |

Stainless Steel | 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.8, 0.9, 1.0, 1.2, 1.5, 1.6, 2.0, 2.3, 2.5, 3.0, 3.2, 4.0, 5.0, 6.0, 8.0, 10.0, 12.0, 16.0, 18.0, 20.0, 25.0 | In general, the tolerance is ±0.1mm for material thickness of less than 3mm. For material thickness of 3-6mm, the tolerance is ±0.15mm. For material thickness greater than 6mm, the tolerance is ±0.5mm. |

Copper/Brass | 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.8, 0.9, 1.0, 1.2, 1.5, 1.6, 2.0, 2.3, 2.5, 3.0, 3.2, 4.0, 5.0, 6.0, 8.0, 10.0, 12.0, 16.0, 18.0, 20.0, 25.0 | In general, the tolerance is ±0.1mm for material thickness of less than 3mm. For material thickness of 3-6mm, the tolerance is ±0.15mm. For material thickness greater than 6mm, the tolerance is ±0.5mm. |

Available Finishes For Sheet Metal

Aluminum and copper will oxidize when exposed to air, while steel will rust. This is why adding a proper finish to sheet metal parts is essential and will help us extend the parts' life.

- Bead blasting

- Brushing

- Polishing

- Anodizing

- Powder coating

- Painting

- Electroplating

- Silk screening

- Laser engraving

Client's Feedback

FAQ About Sheet Metal

The thickness of the painting is 20-180μm while the powder coating is 50-200μm. With thicker film, powder coating can protect the pieces better and prolong the service life. Painting always has a more smooth and glossy surface. There is little price difference between painting and powder coating for normal color. If you want to custom paint or powder coating color, RAL or Pantone code is needed.

Turnkey is able to offer cutting, bending, punching, welding, and even riveting. With our own sheet metal factory, we can ensure the lead time and start with 1 piece. There are also many finish options for sheet metal that you can get from Turnkey. Assembly service is also available from Turnkey.

Our max bending capability is 3000mm, if your design is within our limit, we can handle it. As to specially designed projects (too long or too thin), we will use suitable protective material, for example, board, wooden stick, tape, foaming materials, and others to make sure the parts are in good condition

Because of the structure of sheet metal, the parts are always light in weight but heavy in volume weight. It will take lots of money to ship if the size is too big. Normally we suggest you ship large sheet metal parts by sea to lower the cost, however, the shipping time will be longer.

For some basic V-shape or U-shape die, we have some dies with standard size and if your project can use our dies, there won’t be any extra cost. However, if you have future plans for your sheet metal projects, which were mentioned with our team before, we will keep the dies for you for a certain period.

Sure! Every piece in Turnkey will be perfectly grinding after the welding process to make sure the welding area is flat and smooth. This is not only for our requirement, but also for further finish actions. After grinding and finishing, it is hardly possible to find the welding trace.

Based on our current capabilities, the max size we can handle is 3 meters long. However, for such a size part, normally we will suggest doing the shipment by sea as the cost will be greatly high if shipped by air.

There are some points important for our quotation, for example, quantity, design, structure, material, and finish. All the factors mentioned above will more or less influence the cost. For one piece, we will still go through the whole process, just like more pieces. So, on average the total cost, and price for one piece will be higher than for bigger quantities.

Our default finish for sheet metal is as cut, but normally we will do some debur actions here to prevent hurting the edges since they are very shaped after cutting.

Generally, the lead time for tool and die manufacturing depends on the complexity of the punch design, the number of total operations needed to produce your part (for progressive stamping), and the quantity of parts required. Single-stage tooling usually takes roughly 4 to 6 weeks to produce; progressive tooling usually takes 8 to 10 weeks.

Which Designs Will Reduce Your Sheet Metal Costs?

The array of the sheet metal parts allows for a reduction in material waste, an increase in material utilization and a reduction in material costs.

Standard material thicknesses are more economically priced in the material market. If the thickness of the sheet needs to be customized, the material cost will increase.

When the material thickness is less than 0.5mm, the part is prone to deformation during machining. If the deformation is unacceptable, there will be increased labor costs to straighten the part.

Narrow and long features not only have low part strength, but they also waste a lot of material when cutting. When mass production comes around, narrow and long features will increase the cost of the stamping tool.

Using a simple profile instead of a concave-convex profile, which requires a concave or convex mold to be made, will increase the cost of the mold.

The impact on costs of complex bending during the prototype phase is small. But when mass production comes, each bend will require 1-2 sets of tooling to complete and tooling costs will increase.

Laser cutting and bending cannot meet precise dimensional tolerances. When dimensional tolerances are less than ±0.05mm, CNC milling is required to help it complete the precision machining and manufacturing costs will increase.

When the bending edge length is less than a certain value, the sheet will not be bent. We need to extend the bending edge length and then cut off the excess length after the bending is completed, which will increase the material and manufacturing costs. In general, the minimum bending edge length can be designed to be more than 3 times of the thickness.

When the general sheet thickness is less than 6mm, the inner radius of the sheet bending can be directly equal to the sheet thickness. When 6 < sheet thickness < 12mm, the inner bending radius of the sheet is generally 1.25~1.5 times the sheet thickness. When the sheet thickness is greater than 12mm, the sheet bending radius is generally chosen to be 2 to 3 times the sheet thickness. If the bending radius is out of range, it needs to be processed with a customized special mold and the manufacturing cost will increase.

There are many ways to assemble sheet metal, and a reasonable assembly method is closely related to the cost.

Snap ≤ blind riveted≤ riveted ≤ welded ≤ common screw ≤ manual screw

Try to use standard holes and slots for sheet metal features, non-standard features will take more machining time and will cost more to manufacture.

Whenever possible, choose standard fasteners for the connection of sheet metal parts. Customized fasteners will increase manufacturing costs.

Pros and Cons of Sheet Metal

Prons

1. Simple process.

Complex structures can be manufactured by simply cutting, bending and welding.

2. Easy to shape.

It can be bent into many shapes and still retain its strength and structural integrity.

3. Strength and durability.

The one-piece construction greatly guarantees the strength and durability of the sheet metal.

4. Cost-Effective

Small machining volumes, low material waste, and economical manufacturing costs compared to CNC milling.

5. Variability

Easy to cut, weld and can manufacture large and complex components.

Cons

1. Cost will be high if quantity is small

The sheet metal process is simple but complex and it requires a lot of equipment to work together, so start-up costs are high. When the quantities are small, the start-up costs borne by each part will be expensive.

2. Limited design.

Sheet metal is only suitable for thin sheet construction and cannot be completed by bending if the thickness of the board exceeds 20 mm.

3. Lower manufacturing accuracy than CNC milling.

Compared to CNC milling, sheet metal fabrication is less precise. If dimensional tolerances are less than ±0.01mm, CNC milling is required to assist in the work.

4. Deformation.

When welding is involved, the sheet metal will deform under the effect of thermal expansion and contraction. The tolerance of the weld position will not be guaranteed. The larger the weld area, the greater the distortion.

Book a meeting with our project engineer today

If your files are out of the limit, please kindly send your files to info@besturnkey.com. Thank you.

*All uploads are secure and confidential.