Custom Injection Molding Service

T1 Samples As Fast As 2 Weeks

- MOQ 100pcs

- Free DFM Feedback

- Support Prototype Injection Molding

Our Injection Molding Processes

Injection molding is widely used in mass production as it is fast and cost-effective. Here in Turnkey, we will offer various injection molding solutions for you in different industries.

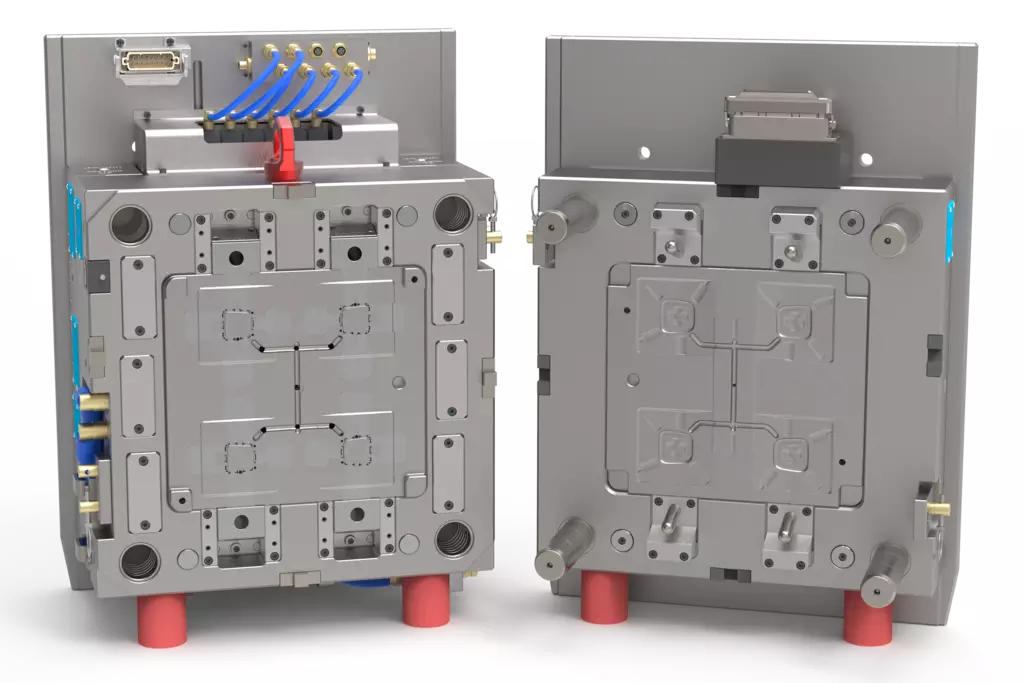

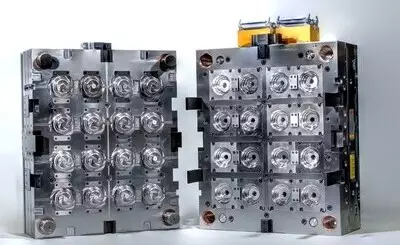

Mold Manufacture

Mold manufacturing is the process of making molds for production by CNC machining, EDM, and other processes according to drawings.

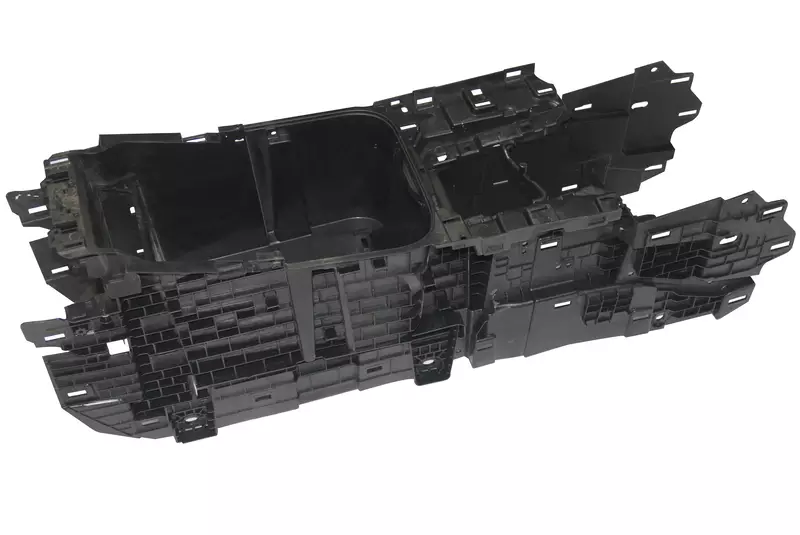

Plastic Injection Molding

It is a process of heating & melting thermoplastic or thermosetting material, then injected into a mold cavity to solidify & form.

Liquid Silicone Rubber Molding

A & B liquid silicone rubber raw materials will be injected into the mold cavity after fully mixing, then heated and rapidly vulcanized in the hot mold cavity.

Insert Molding

Insert molding is a combined two-part injection molding process where one material is overlaid on a metal insert, then form them to be one part.

Why Choose Turnkey for Custom Injection Molding?

Intelligent Manufacturing Service

Lower risk & cost. DFM report will help you optimize design if necessary

Save communication time & cost. No need to find other partners for different processes

One-stop service. We can support “Design-> Manufacture->Assembly” one-stop delivery

Clear update. You will know every step of your project with detailed photos. No need to worry

Traditional Manufacturing Service

High risk & cost. Without a DFM report in the early stage, problems may occur during the manufacturing

Long communication time & cost. Have to talk with several suppliers for different processes

Single service. May pay extra cost for assembly after collecting the parts from suppliers

Unclear update. You are the last one to know if any delays and have no idea about the delivery schedule

Unstable quality. No clear quality control process and may have problems if any information was not shared

Turnkey's Capability for Injection Molding

Mold injection is complex, and we need to set many parameters to ensure the quality of the parts.

Max part size | 1500*800*600mm |

Min part size | 1*1*1mm |

Max tooling size | 3000*1500*1500mm |

Min tooling size | 80*80*300mm |

Min part tolerance | ±0.01mm |

Standard part surface | SPI-C3 |

Mold life | Production tooling about 500000 shots Rapid tooling about 5,000-10,000 shots |

Lead time | For toolings, the production tooling is machined in 2-3 weeks, and the rapid tooling is machined in 7-10 days. For parts, as low as 2 weeks for T1 samples. After T1 sample approval, lead time for < 10,000 parts is as low as 1 week. |

T1 samples | 5-10 sets (pieces) of samples are supplied in each mold trial. |

Max press size | 2400T |

Min press size | 100 parts |

Mold storage | Stored for 2 years of inactivity |

How to Lower Costs During the Development Cycle?

You can validate designs and choose the right material before mass production in an affordable way.

|  | |

Prototype Injection Molding | On-Demand Manufacturing | |

Application | 1. Iterate on materials and designs, and evaluate cost and manufacturability. 2. Lower manufacturing risk. 3. Improve product development speed and shorten time to market. | 1.For finalized product design |

Cost for manufacturing molds | Cost effective | Expensive |

Mold production time | 7-10 days | 2-3 week |

Mold material | Steel or aluminium | Steel |

Lifespan | 5000-10000 shots | 500000 shots |

Let's Talk About Your Project

Optional Materials for Parts

We have more than 100 kinds of thermoplastic and thermoset materials to choose from.

AAS, ABS, ABS/PC, EPDM, ETFE, HDPE, LCP, LDPE, LLDPE, PA, PA6, PA66, PAA6, PBI, PBT, PC, PDAP, PE, PEBA, PEEK, PEI, PET, PETP, PI, PMMA, POM, PP, PPC, PPE, PPS, PPVC, PS, PSU, PTFE, PVB, PVC, PVCC, PVDC, PVDF, TPE, TPU, UHMWPE.

Standard silicone (30, 40, 50, 60, and 70 durometers), Medical-grade silicone, Optical-grade silicone, Fluorosilicone (fuel and oil resistant)

Optional Surfaces for Mold

Glossy | Semi-Glossy | Matte | Textured |

SPI-A0 | SPI-B0 | SPI-C1 | MT (Moldtech) |

SPI-A1 | SPI-B1 | SPI-C2 | YS (Yick Sang) |

SPI-A2 | SPI-B2 | SPI-C3 | VDI (Verein Deutscher Ingenieure) |

SPI-A3 | SPI-B3 | / | / |

Secondary Operations

We have more options for the parts if you have any special requirements for the appearance.

- Inserts

- Heat staking

- Painting

- Silk screening

- Ultrasonic plastic welding

- Laser engraving

- UV coating

How Does Injection Molding Work?

- The melt resin material will be injected into the mold, and after shaping and cooling, the product will be knocked out

- The speed of the knocking-out process shall depend on the product structure and material

- The distance of knocking out should be 1-2cm longer than the vertical thickness of the product. After knocking out, the ejector will go back and the whole process will repeat many times for more pieces

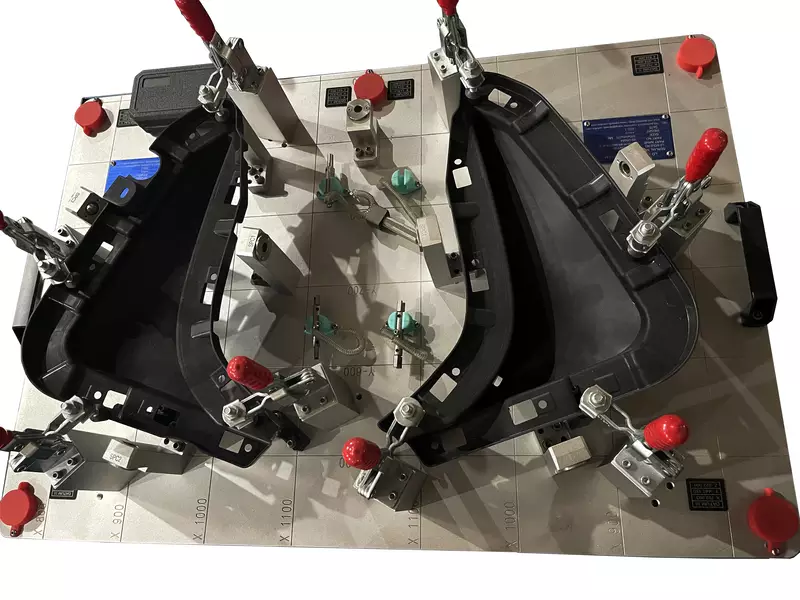

We Strictly Follow International Quality Standards

- ISO9001:2015

- ISO14001:2015

- Customized Fixture

- Material Certificate

- RoHS/SGS Report

Clients' Feedback

FAQ About Injection Molding

It sometimes happened that T1 samples can not meet your requirement. In Turnkey, we can support T2 and even T3 if the samples are not available for you. During every process, 5~10 samples will be sent and your team can fully test if the mold is acceptable.

Export molds are available here in Turnkey. If you prefer to have molding parts in your factory, we can make the molds for you and arrange the shipment accordingly.

There are many factors that influence the cost of injection molding parts, for example, the material, the structure of your design, quantity, mold material, mold texture, and so on. If you want to control your project budget, we will offer you the solution accordingly.

Normally we will keep the molds for two years free of charge once confirmed. However, we fully understand that some projects have longer service time, in this case, please contact us for a longer storage period.

If the design does not change too much and the previous mold can be used, we will fix the mold as per your updated design. If the design changes too much and we can not use the previous mold, our team will quote you a new price based on your updated design.

Basically, it will depend on the quantity, quality, and further plans for your project. If only plan for small batches, in this case, prototype molding will be a good choice, as it is fast and more cost-effective than production molding. However, if the project shall have a long service life and possibly for years, production molding should be chosen to lower the total cost and time.

We are able to offer glossy(SPI-A0, SPI-A1, SPI-A2 & SPI-A3), semi-glossy(SPI-B0, SPI-B1, SPI-B2 & SPI-B3), matte(SPI-C1, SPI-C2 & SPI-C3) and textured(MT, YS & VDI) finish for molds. If you are not sure about the standard, you can send us a sample picture for reference. Then, our team will quote you a similar finish for your mold.

Yes, Turnkey is able to offer SPI-A1 without any problem. Moreover, if you want some secondary options, for example, nickle plating and chrome plating for better appearance.

There are two types of resins to choose from: amorphous (plastic cutlery and electronic components) and semi-crystalline (bottles, packaging, pipes, and medical implants). Each type of resin is available in affordable, moderate, and high-performance solutions. When selecting a plastic resin, you should begin by choosing the family of materials that will give you most of the properties you want. The right resin guarantees optimum product performance, so please contact us to get more information from us and determine the ideal choice for your project.

The actual model represents the most significant expense in the entire production process. Individuals should consider working with precision molds made from high-quality steel because they last for years. Please kindly note that many factors contribute to the cost of a mold in a custom plastic injection mold project. Send all your files to us and we will quote you the exact price.

Book a meeting with our project engineer today

If your files are out of the limit, please kindly send your files to info@besturnkey.com. Thank you.

*All uploads are secure and confidential.