Materials

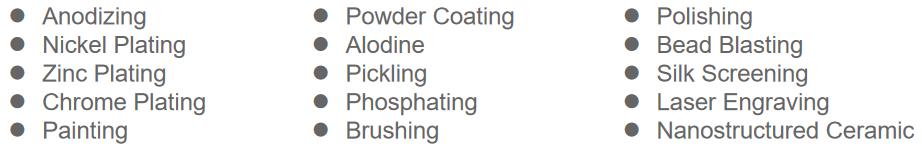

Aluminum

Aluminum alloy is a material mainly composed of aluminum elements and mixed with a small amount of metal alloying elements such as copper, magnesium, manganese, silicon, tin, nickel, zinc and etc. After adding alloying elements to aluminum, its mechanical properties are significantly improved, and the inherent characteristics of light weight can be still maintained, which is a great help to the development of aerospace industry. Meanwhile, it is highly inclusive and can be perfectly combined with a variety of surface finishes.

- 2000 Series Aluminum:AL2014, AL2017, AL2024, AL2030

- 5000 Series Aluminum:AL5052, AL5005,AL5754,AL5083

- 6000 Series Aluminum:AL6060, AL6061, AL6063, AL6082

- 7000 Series Aluminum:AL7075

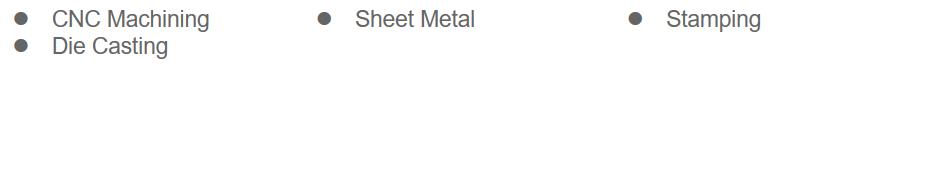

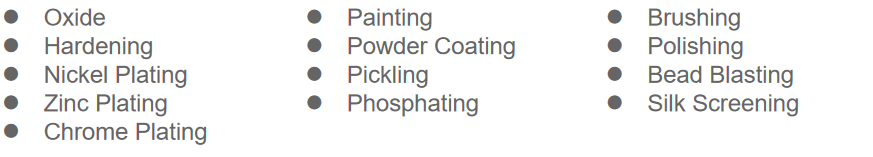

Steel

Steel is a general term for iron-carbon alloys with a carbon content between 0.02% and 2.11%. It also contains a small amount of manganese, phosphorus, silicon, sulfur and other elements. Different ratios of elements determine the hardness, corrosion resistance and brittleness of the steel. The density of steel is high, but it can provide irreplaceable strong hardness, which is especially friendly to parts that need strong force.

- Stainless Steel: SUS303, SUS304, SUS316

- Tool Steel: 1.2311, 1.2363, 1.2379, 1.2767

- Carbon Steel: Q235, Q275, S45C

- Alloy Steel: 4140, 4130, 4340

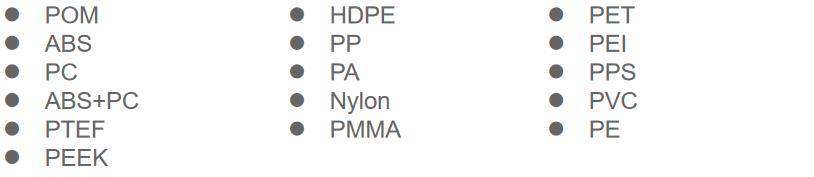

Plastic

Plastic is lighter and less rigid than metal. Most plastics are lightweight, chemically stable, do not rust, color well with low machining cost. However, it has poor heat resistance and is easy to deform under thermal expansion and contraction. During the process of use, we should pay attention to the “white pollution” caused by waste plastics and use plastic products scientifically.

Brass

Brass is an alloy of copper and zinc. The copper content is about 60% while the zinc content is about 40%. The surface is light golden yellow. Compared with other metal materials, brass has relatively high density and price. But it has good electrical and thermal conductivity which made it a good choice for CNC machining.

Copper

Copper is relatively pure copper, the content of copper reaches 99.9%, and the surface is dark red. It fully expresses the ductility, conductivity and corrosion resistance of metallic copper. The dark red metallic luster gives it a calm and noble quality while expressing a modern sense, and it is the most commonly used material in copper ornaments.

Magnesium Alloy

Magnesium has low density, high strength, and good heat dissipation and shock absorption. However, it is easy to oxidize and get burnt, has poor heat resistance, and is easy to catch fire during machining. It is very popular in aviation, aerospace, transportation, chemical and rocket making industry.

Titanium Alloy

Titanium stands out among many materials with its high strength, good corrosion resistance and high heat resistance. It can work for a long time at a temperature of 450 to 500 ° C, and is especially suitable for the manufacturing of aircraft and various spacecraft.

- TC2, TC4, TC5

- Food-grade Titanium Alloy

- R53400 Titanium Alloy 9

Zinc Alloy

Zinc alloy is a material mainly composed of zinc and mixed with a small amount of metal alloying elements such as aluminum, copper, magnesium, cadmium, lead, and titanium. Zinc alloy has good fluidity and castability with a low melting point, which can die-cast precision parts with complex shapes and thin walls. It is pretty popular in the field of die casting.