Finish Service Details

For different materials and effects, we have many finish options as below. If you can not find your desired finish in the below sheet, please contact us at info@besturnkey.com.

Anodizing

After anodizing, one layer of oxide film will be formed on the aluminum surface, and the oxide film can prevent aluminum from oxidizing in the air to form spots. It usually comes together with bead blasting.

Suitable materials: Aluminum, magnesium alloy

Color: Clear, black, red, yellow, blue, gold, rose gold, customized colors available

Texture: Smooth, matte

Coating thickness: 5-50μm

Min tolerance for coating thickness: ±3μm

Test tools: Coating thickness meter, colorimeter

Bead Blasting

Bead blasting uses fine sand particles to impact the surface of the part, causing the surface to produce granulated depressions. It can remove burrs and machining marks on the parts. Bring unique fog vision.

Suitable material: All materials

Specification: 60#, 80#, 100#, 120#, 150#, 180#, 220#

Types: Copper ore, quartz sand, emery, iron sand, Hainan sand

Gloss: Matte

Test tools: Bead blasting comparison standard sample

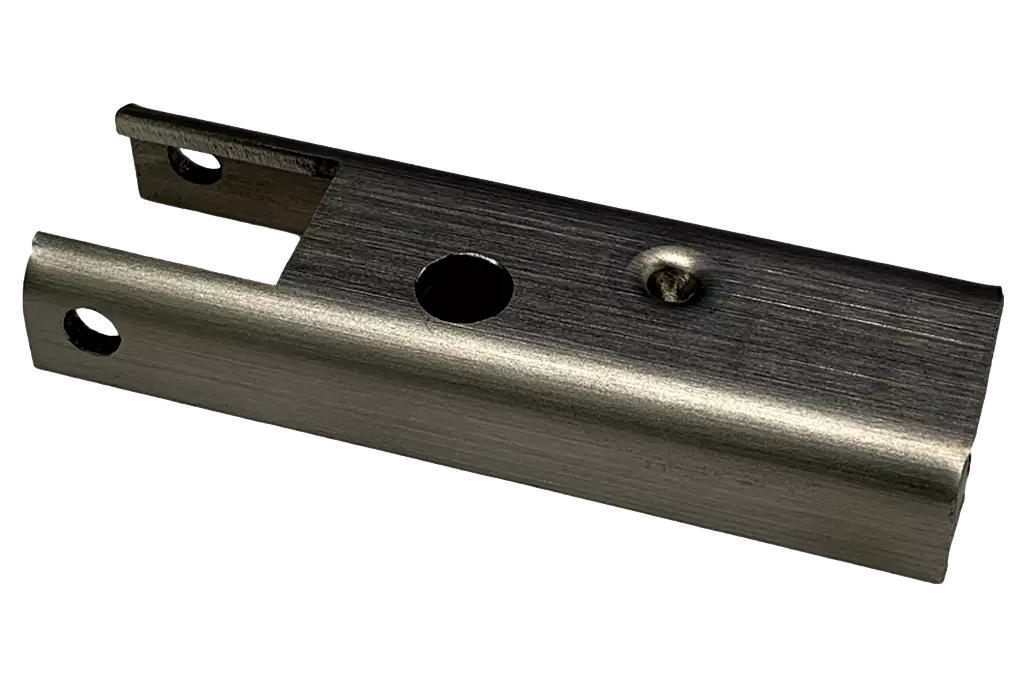

Brushing

Brushing uses sandpaper to reciprocate on the surface of the part, giving the surface of the part a regular linear texture. It can improve the surface finish of the parts, and cover the slight scratches on the surface, which has a good finishing effect.

Suitable material: Available for most materials

Specification: 60#, 80#, 100#, 120#, 150#, 220#, 240#

Types: Mechanical brush, hand brush

Texture: Smooth

Test tools: Brush comparison standard sample

Electroplating

Electroplating is using the metal principle to coat a thin metal protective film on the surface of the parts. It is mainly manifested in the characteristics of wear resistance, electrical conductivity, and protection and decoration.

Suitable material: Aluminum, steel, copper, magnesium alloy, zinc alloy

Types: Chrome, zinc plating, copper plating, nickel plating

Gloss: Smooth, shiny

Coating thickness: Related to the part material

Min tolerance for coating thickness: ±5μm

Test tools: Coating thickness meter

Hardening

There are two kinds of hardening: appearance hardening and totally hardening. The first one only hardens the part’s surface, but the center is still soft while the second one hardens the whole part.

Suitable material: Steel

Test tools: Hardness tester

Laser Engraving

Laser engraving is used to make some special logos or numbers on the parts by laser, to help us separate them. Compared with CNC milling engraving, laser engraving is more cost-effective.

Suitable material: All materials

Color: Nature, dark gray, black

Depth: 0.1-0.3mm

Laser engraving drawing format: *.CAD, *.AI

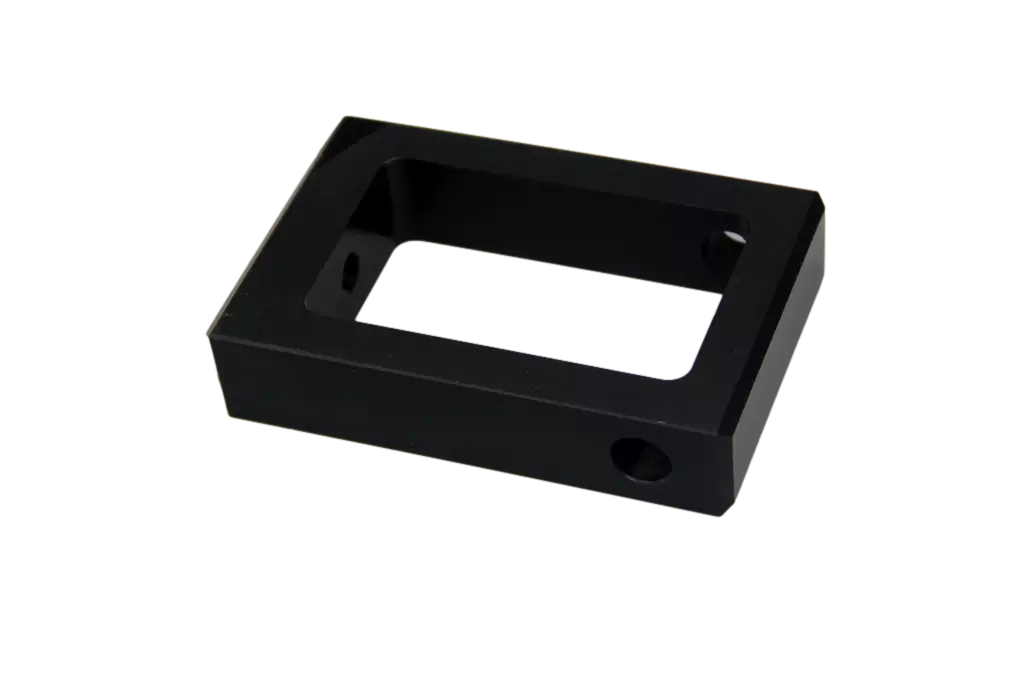

Oxide

In order to protect the surface of steep parts, we will immerse the parts in a strong oxidizing chemical solution to form a beautiful, dense, and rust-proof black oxide film, which is called oxide. We can often find this finish on screws, nuts, and some fasteners.

Suitable material: Steel

Color: Black, brown

Coating thickness: 0.5-1.5μm

Texture: Smooth, matte

Test tools: Coating thickness meter

Painting

Painting uses compressed air to disperse the liquid paint into mist-like particles and adhere to the surface of the part. The coating is thinner than powder coating, the surface is smooth and glossy, and has an excellent decorative effect.

Suitable materials: Aluminum, steel, copper, plastic

Painting particle size: Fine, medium, coarse

Color: Can be customized by RAL or Pantone code

Texture: Matte, semi-matte, glossy

Position: Partially, completely

Coating thickness: 20-180μm

Min tolerance for coating thickness: ±20μm

Test tools: Coating thickness meter, colorimeter

Polishing

Polishing is a process of sanding a part smooth or shiny using physical or chemical tools. It can not improve dimensional accuracy, mainly for the purpose of obtaining a mirror surface.

Suitable material: All materials

Specification: 800#, 1000#, 2000#, 3000#, Max

Types: Mechanical polishing, electropolishing

Test tools: Polish comparison standard sample

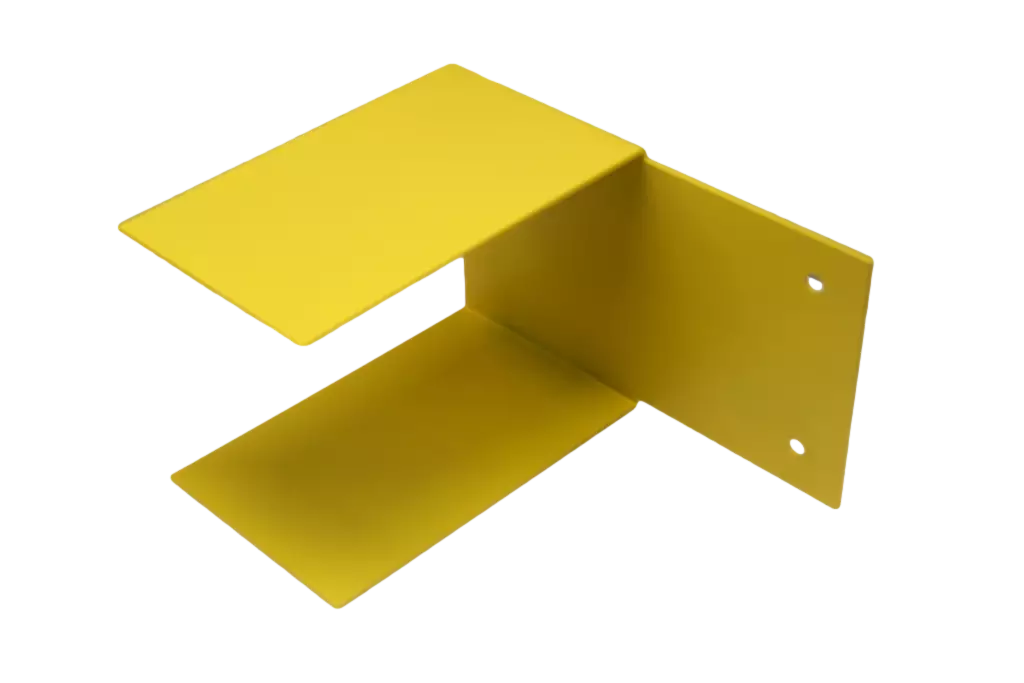

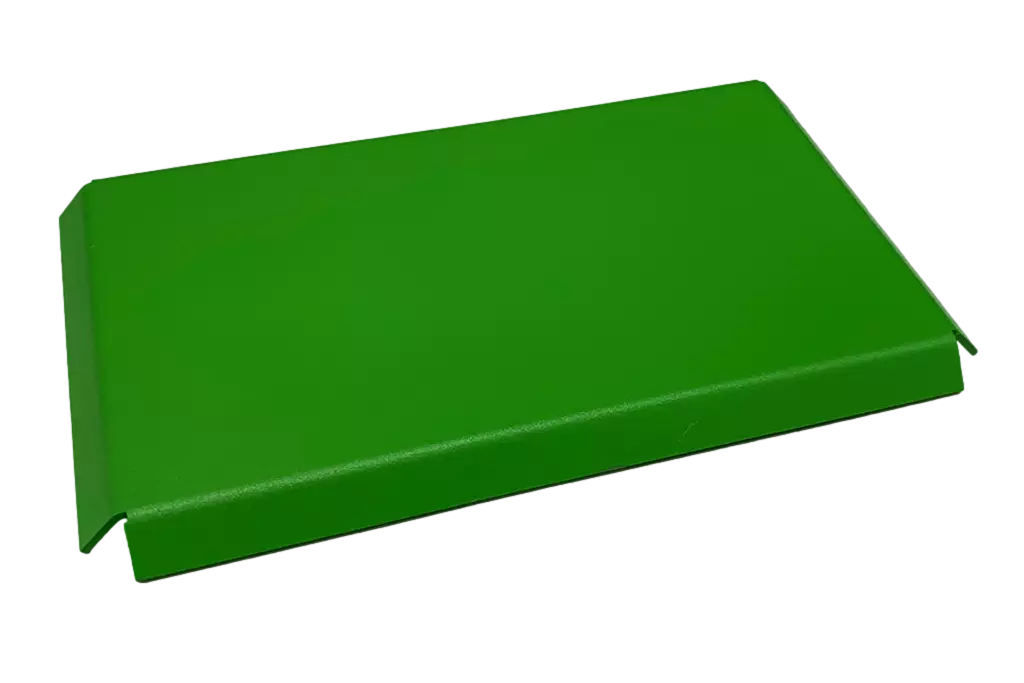

Powder Coating

Powder coating refers to the process of using static electricity to adsorb powder on the surface of parts. Powder coating can protect and prolong the life of the parts. At the same time, it has an excellent decorative effect.

Suitable material: Metals

Painting particle size: Fine, medium, coarse

Color: Can be customized by RAL or Pantone code

Texture: Matte, semi-matte, glossy

Position: Partially, completely

Coating thickness: 50-200μm

Min tolerance for coating thickness: ±30μm

Test tools: Coating thickness meter, colorimeter

Silk Screening

Silk screening, also called screen printing, is a marking method to make a specific pattern or logo on the surface of the part and then brush the ink through printing gauze.

Suitable material: Plastic and some metals

Advantages: Long storage time, short lead time

Disadvantages: Limited by the shape of the part, high cost for small batches