All you need to know about stainless steel

Why Stainless Steel Performs So Well

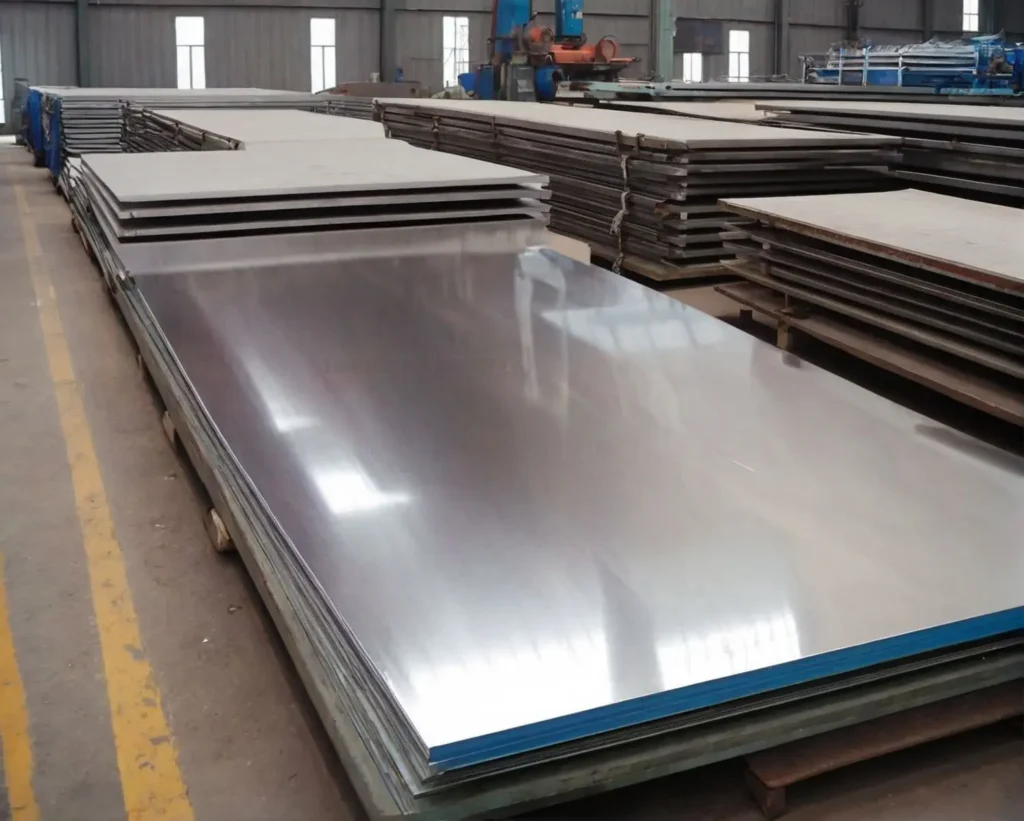

Stainless steel has a wide range of applications in sheet metal processing due to its good plasticity and processability. Reasonable use of various sheet metal technology can make stainless steel to play a maximum effect, stainless steel will be used in different fields because of the proportion of its metal elements.

Iron (Fe) is the base metal of stainless steel, accounting for over 50% of the composition; chromium (Cr) is generally required to be 10.5-30% to form a dense, protective oxide film on the surface for corrosion resistance; nickel (Ni) at 8-20% enhances ductility, toughness and corrosion resistance; carbon (C) is usually kept below 0.08% to maintain corrosion resistance while improving strength; silicon (Si) up to 1% improves corrosion resistance and stabilizes the austenite structure; molybdenum (Mo) at up to 4% increases resistance to pitting and carbon penetration; small amounts of cobalt (Co) reduce sulfide precipitation for better corrosion resistance; titanium (Ti) stabilizes carbides and increases resistance to crevice corrosion when added in small quantities; aluminium (Al) in minor quantities is used for deoxidation and austenite stabilization; phosphorus (P) improves corrosion resistance in small amounts; therefore, stainless steel derives its excellent corrosion resistance from the careful balancing of all these alloying elements and proper selection of composition is critical.

Properties of Stainless Steel

Stainless steel is used in a wide range of industries because of its many properties and proven processing methods, and is one of the most common materials used for domestic and industrial purposes.

- Affordable and easy to purchase.

- Aesthetic surface and a wide range of possibilities for use.

- Good corrosion resistance and long-lasting appearance.

- High strength, so it is possible to use it in thin sheets.

- High resistance to oxidation at high temperatures and high strength to resist fire.

- Normal temperature processing, easy bending.

- No need for surface treatment, easy maintenance.

- Clean, high finish, can be used in the food industry.

- Good weldability and comprehensive performance.

- Folding resistance, easy to process.

Classification of stainless steel

- according to the thickness of classification:

- thin plate

- plate

- thick plate

- extra thick plate

- according to the production method:

- hot-rolled steel plate

- cold-rolled steel plate

- according to the surface characteristics of classification:

- galvanized sheet (hot galvanized sheet, galvanized sheet)

- tin plate

- composite steel

- color coated steel

- according to the use of classification:

- bridge steel plate

- boiler steel plate

- shipbuilding steel plate

- armor plate

- automotive steel plate

- roofing steel plate

- structural steel plate

- electrical steel plate (silicon steel sheet)

- spring steel plate

- other

Common Japanese grades for general and mechanical structural steel plates

- Japanese steel (JIS series) in the grade of common structural steel mainly consists of three parts: the first part of the material, such as: S (Steel) that the steel, F (Ferrum) that the iron; the second part of the different shapes, types, and uses, such as P (Plate) that the plate, T (Tube) that the tube, K (Kogu) that the tool; the third part of the characteristic Number, generally the minimum tensile strength. Such as: SS400 – the first S said steel (Steel), the second S said “structure” (Structure), 400 for the lower limit of tensile strength of 400 MPa, the overall tensile strength of 400 MPa for the general Structural steel.

- SPHC – the first S for the abbreviation of steel Steel, P for the abbreviation of plate Plate, H for the abbreviation of heat Heat, C Commercial abbreviation, the whole indicates that the general use of hot-rolled steel plate and steel strip.

- SPHD – hot rolled steel plate and steel strip for stamping.

- SPHE – said deep-drawn hot-rolled steel plate and steel strip.

- SPCC – said the general use of cold-rolled carbon steel sheet and strip, of which the third letter C for the abbreviation of cold Cold. Need to ensure that the tensile test, add T at the end of the grade for SPCCT.

- SPCD – that cold rolled carbon steel sheet and strip for stamping, high quality carbon structural steel.

- SPCE – said deep-drawn cold-rolled carbon steel sheet and strip, deep-drawn steel. N is added to the end of the grade for SPCEN when non-ageing is required.

Stainless steel finishing and colors

- The natural appearance and color of stainless steel.

- The surface of stainless steel manufacturers, such as the appearance after specific rolling; mainly divided into rolling surface processing, chemical surface processing, mechanical surface processing, reticulation surface processing and color surface processing.

Some models after heat treatment, the surface of stainless steel is not as smooth as before, and need to be lightly cold rolled.

After light cold rolling, they need to be polished before they can be put on the market.

Stainless steel with high surface requirements will be covered with plastic bags or cardboard, stainless steel plate will be affixed with a layer of plastic film that can be torn to prevent scratches or dust affecting the buyer’s secondary processing.

Many kinds of surface finishing has been using the number or other classification method, they are all codified in the relevant standards, various national standards also have a clear surface finish requirements in order to distinguish between

For laying on the ground or non-slip, the finish to specify the requirements of handrails, station equipment, kitchen appliances, stainless steel manufacturers to add a new pattern rolling and polishing process.

Stainless steel with specified requirements for surface roughness needs to be chemically impregnated by electrolytic polishing, sandblasting, cleaning and other processes to meet national standards.

In order to avoid excessive reflection, resulting in unsightly handprints, there are also straight wire grain, snow grain, nylon grain processing. - Stainless steel color film, mainly used in architecture and interior design, this type of stainless steel thickness is very thin, the use of stainless steel lines of beauty, thin, easy to fix and other characteristics of the completion of the home decorating design. Etching, embossing, mirror, messy pattern, retreat bowl, brushed, sandblasted, copper plated nano is our common stainless steel home style.

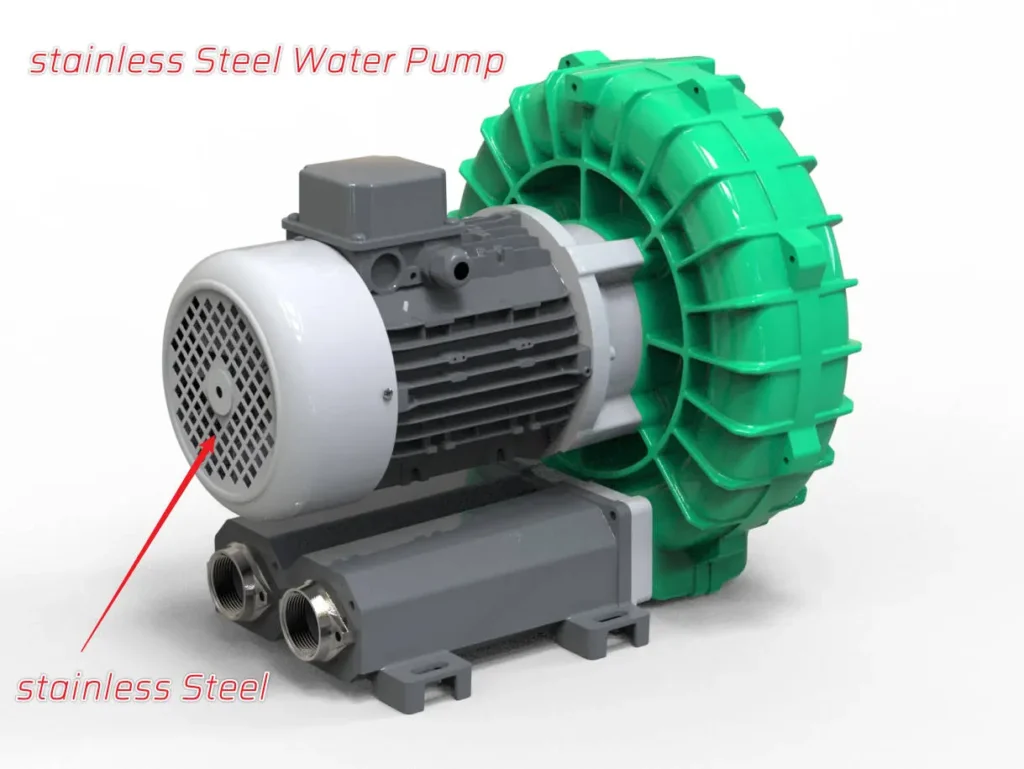

Stainless steel production equipment & engineering project- Main features

Electric ArcFurnace(EAF) – The main raw material of alloy iron (ferrochrome, ferronickel) is added to the general steel for proper mixing, and then melted in the electric furnace by the heat generated by the electric arc.

A.O.D or V.O.D – In the electric furnace melting stainless steel water rolled into the refining agent deoxidizing, blowing into the inert gas – argon, reducing the content of carbon and sulfur, while regulating the chemical composition.

ContingCasting – Stainless steel water refined in the refining furnace, the engineering of raw slightly cast ingot blocks, equipment for direct manufacture of flat billets.

Furnace – A device that heats a flat blank (blank) to a hot rolling temperature.

Rough HotRolling – A device that heats blanks (flat blanks) in a furnace and is hot-rolled to produce plates.

Finish Hot Rolling – After one hot roll, the stainless steel pattern plate is rolled again to form a hot rolled coil and a device to control the final thickness of the quantity.

H-APLAnnealing&Pickling Ling By annealing, the hot rolling stress caused by hot rolling is eliminated and the normal metal structure is restored, and the debris generated during hot rolling is pickled and the final hot rolled coil is made.

CGLCoil Grinding Ling – Equipment that adjusts the surface flatness by grinding different defects that occur on the surface of the product during hot rolling, especially the corrosion pits caused by continuous annealing of hot rolling and pickling.

Coil Building-up Ling(CBL) – Designed to improve product yield, the other function of this machine is the surface quality inspection of raw materials.

ZRM20-hi SendzimirMill – Like stainless steel, rolling mills that require high-strength, high-precision products are specifically designed for cold rolling.

Annealing&Pickling Line(APL) – The internal structure of stainless steel that occurs in cold rolling, which returns to normal by heat treatment, while high-temperature oxides occur during heat treatment.

Skin Pass Mill(SPM) – The process of rolling products after cold rolling with a very small amount of pressure is to obtain the improvement and nuclear integrity of the mechanical properties of the product, and to obtain a metal luster.

Coil Polishing ling(CPL) – The processing process of final surface grinding according to the surface state of the user’s requirements.

Slitting Ling(STL) – The products that have been processed in the previous project are cut according to the length and width specified by the user’s requirements.

Shearing Ling(SCL) – The products that have been processed in the previous project are cut according to the length and width specified by the user’s requirements.

Series grades of stainless steel

200 Series Austenitic Stainless Steel

Grade 201 Stainless Steel

Grade 202 Stainless Steel

300 Series Austenitic Stainless Steel

Grade 301 Stainless Steel

Grade 302 Stainless Steel

Grade 303 Stainless Steel

Grade 304 Stainless Steel

Grade 308 Stainless Steel

Grade 316 Stainless Steel

Grade 317 Stainless Steel

317 stainless steel due to the addition of aluminum, 317 stainless steel in molybdenum content slightly higher than 316 stainless steel. Pitting and creep resistance superior to 316 L stainless steel for petrochemical and organic acid resistant equipment.

Grade 321 Stainless Steel

Grade 330 Stainless Steel

330 stainless steel is an austenitic nickel-chromium-silicon-iron alloy with excellent oxidation resistance and carburizing strength up to 2,200°F. Due to the high nickel and chromium content of the alloy, excellent oxidation resistance and carburization properties are provided; applications include chemical and petrochemical, ore processing equipment, heat treating equipment, power generation equipment is an austenitic nickel-chromium-silicon-iron alloy with excellent oxidation resistance and carburizing strength up to 2,200°F. Due to the high nickel and chromium content of the alloy, excellent oxidation resistance and carburization properties are provided; applications include chemical and petrochemical, ore processing equipment, heat treating equipment, power generation equipment.

Grade 347 Stainless Steel

Grade 348 Stainless Steel

348 stainless steel is a stainless steel suitable for the nuclear power industry, which has certain restrictions on the combination of tantalum and drill. 348 is widely used in the chemical industry, such as storage tanks, pipelines, valves, chemical, petroleum and pharmaceutical, etc., because of its corrosion resistance, oxidation resistance and stable mechanical properties In the field of forging, 348 stainless steel is heated uniformly to a forging temperature of 1150-1230 °C, and it is necessary to pay attention to the minimum starting forging temperature can not be lower than 925 °C. Forgings can be air-cooled, but for maximum corrosion resistance, forgings must be water quenched or subsequently annealed.

400 Series Austenitic Stainless Steel

Grade 405 Stainless Steel

Grade 408 Stainless Steel

Grade 409 Stainless Steel

Grade 410 Stainless Steel

Grade 416 Stainless Steel

Grade 420 Stainless Steel

Grade 430 Stainless Steel

Grade 440 Stainless Steel