Your One-Stop Solution for EV Battery Accessories

- Battery Cover

- Battery Tray

- Cooling Plate

- Heatsink

Our Services

Turnkey provides one-stop solution for EV battery accessories, our customized battery accessories and top cooling system solutions can help you to win the leading position in EV area

Battery Cover

Protect your battery for longer service life.

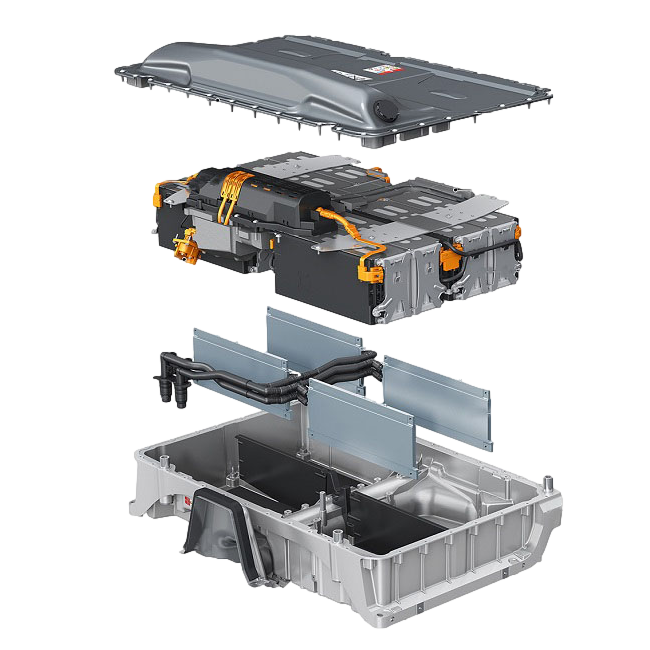

Battery Tray

Protect batteries from external impacts during handling and transportation.

Cooling Plate

Control the equipment temperature within the range.

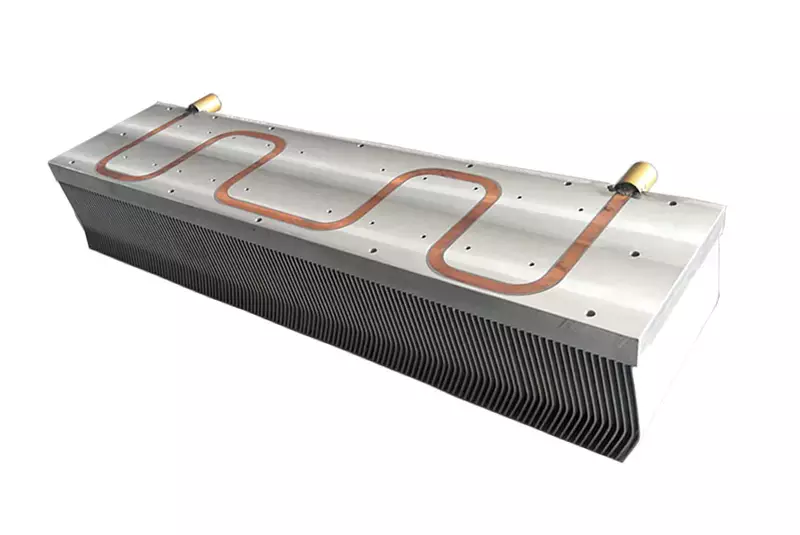

Heatsink

Ensure your equipment continues to work efficiently.

Why Choose Us

Customized Design

Customised designs for your battery accessories to make your product unique.

One-Stop Service

Professional one-stop service to provide you with a full range of new energy battery parts manufacturing solutions.

Low Cost & Risk

DFM reports from our engineering team to help you optimize design, lower budget and shorten lead time.

Strict Quality Control

Manufacturing with high standard to ensure that every accessory is rigorously tested and quality checked.

Custom Battery Cover Service

The battery cover is mainly used to protect the battery from being damaged by external collision and extrusion. It needs to have high temperature resistance, corrosion resistance, abrasion resistance, sealing, insulation, thermal conductivity, strength, rigidity and light weight.

Material  | Process | Finish | Advantages |

Steel | Punching, Stretching, Welding, CNC machining | Painting, Powder coating, Electroplating, Heat treatment, etc | High hardness and strength |

Aluminum | Punching, Stretching, Welding, CNC machining | Anodizing, Paiting, Powder coating, etc | Relatively light, high strength, corrosion resistance, good thermal conductivity |

Carbon fiber | CNC machining | Epoxy Coating | Lightweight, high strength |

Glass fiber | Injection molding | Bead blasting, etc | Lightweight, high strength |

SMC | Compression molding | Powder coating, Electroplating, etc | Lightweight, High strength, Corrosion resistance |

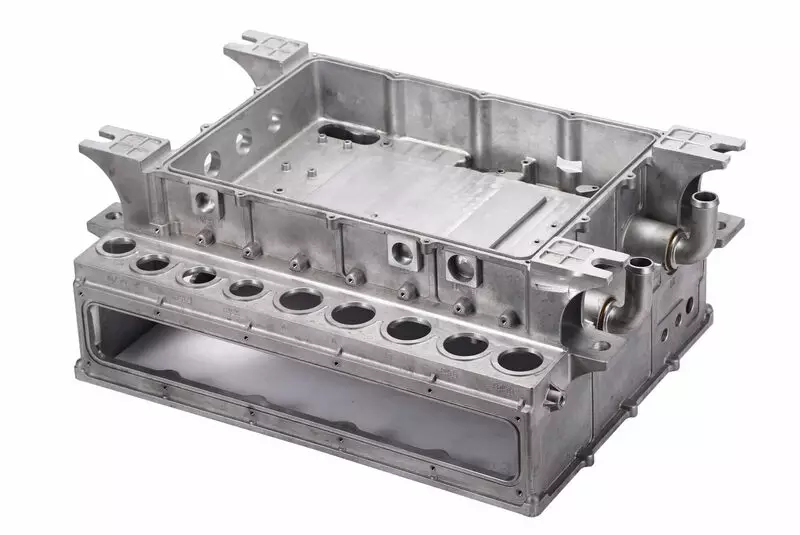

Custom Battery Tray Service

The pallet is mainly used to carry the entire battery pack, which requires high strength and rigidity of the material. At the same time, it needs to have high temperature resistance, corrosion resistance, insulation, thermal conductivity, and lightweight.

Material | Process | Finish | Advantages |

Steel  | CNC machining | Nickle plating, Painting, etc | Corrosion resistance and strength |

Aluminum | Die casting,Extrusion, Friction stir welding, CNC machining | Anodizing, Powder coating, Electrophoresis, etc | High strength and lightweight properties |

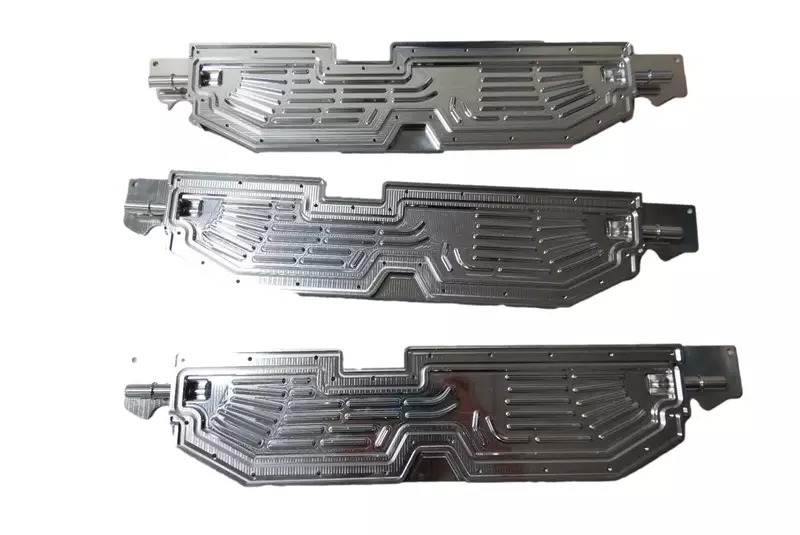

Custom Cooling Plate Service

The cooling plate mainly reduces the temperature of the battery through heat dissipation and cooling to ensure the normal operation and life of the battery. It needs to have heat dissipation, thermal conductivity, corrosion resistance and light weight.

Material | Process | Finish | Advantages |

Aluminum | CNC machining, Friction stir welding | Anodizing, Electroplating, etc | Lightweight, good thermal conductivity and strength |

Copper | CNC machining | Nickle plating, Tin plating, etc | Good thermal conductivity |

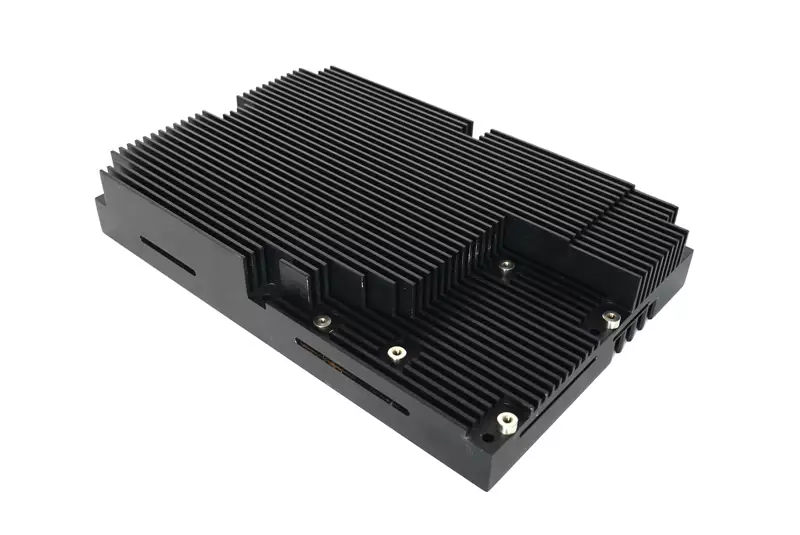

Custom Heatsink Service

Heatsink is to keep the temperature of the battery module within the proper range by dissipating heat to ensure the proper operation and life of the battery.

Material | Process | Finish | Advantages |

Aluminum | Die casting, Extrusion, CNC machining | Anodizing, Powder coating, etc | Lightweight, good thermal conductivity and strength |

Copper | Punching, Laser cutting, CNC machining | Nickle plating, Tin plating, etc | Good thermal conductivity |

About Turnkey

Turnkey is a professional manufacturer certified with ISO9001:2015 and ISO14001:2015, established our first factory in Apr. 2010 with an engineering team of 30 engineers. Aiming to bring more possibilities and choices to engineers and industrial companies, we devoted to support the whole development cycle from prototype to mass production in custom manufacturing. We value every single idea you have and do our best to bring it to life.

Our Quality Control

Uncompromising quality and reliability – This makes your battery pack apart.

- Self-inspection

When a part completes a process, operator A measures the part himself

- Mutual inspection

When the parts go to the next step, Engineer B measures the part first and then works on it

- Professional Inspection

After all the processes, the professional QC team will inspect and check

Our Certificates

- ISO 9001:2015

- ISO 14001:2015

Clients' Feedback