On-Demand Precise CNC Machining Service

From Prototype to Production, No MOQ

- Min Tolerance ±0.005mm

- Fastest Lead Time 2 Days

- Max Part Size 3200*2200*1000mm

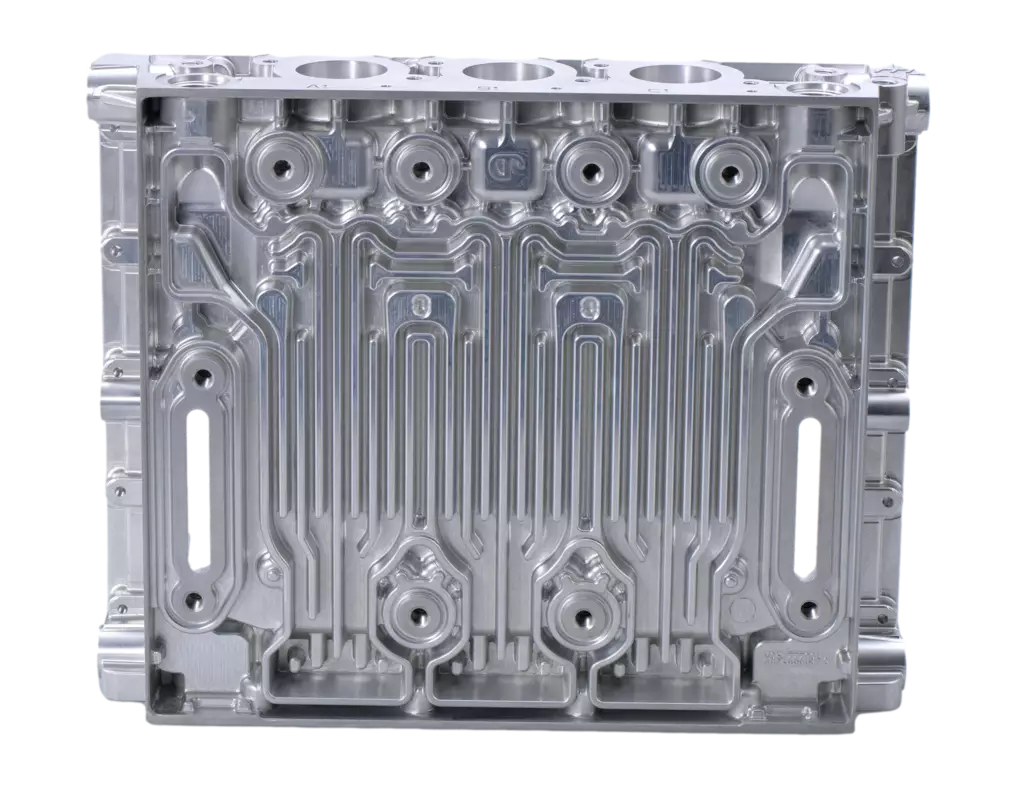

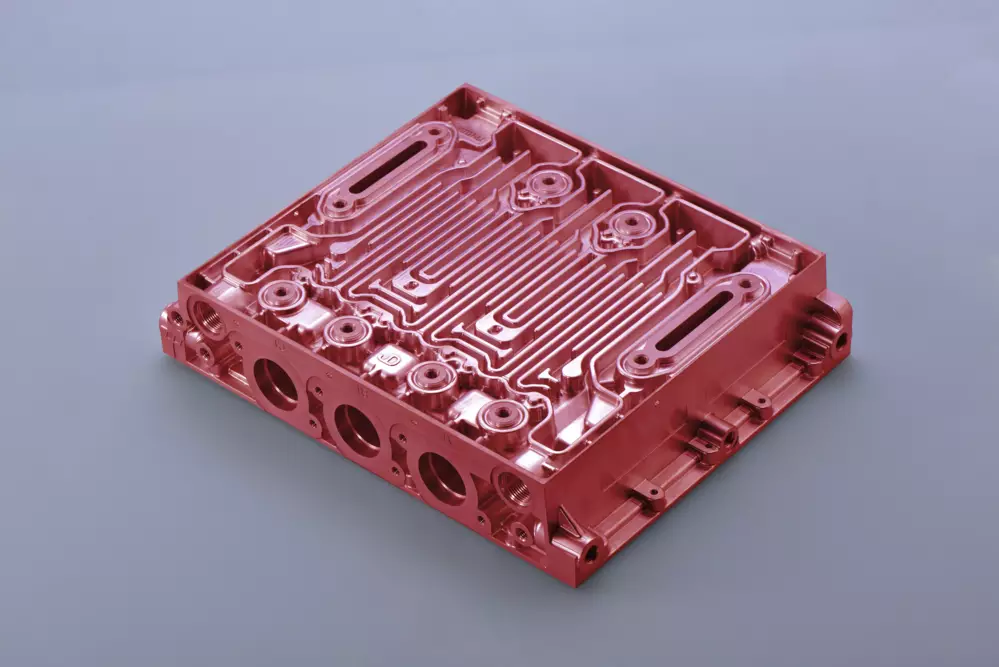

CNC Machining Services

CNC is widely used in the automotive, communications, medical, watch, cell phone, computer, and other industries, which is more suitable for some industries that require high precision.

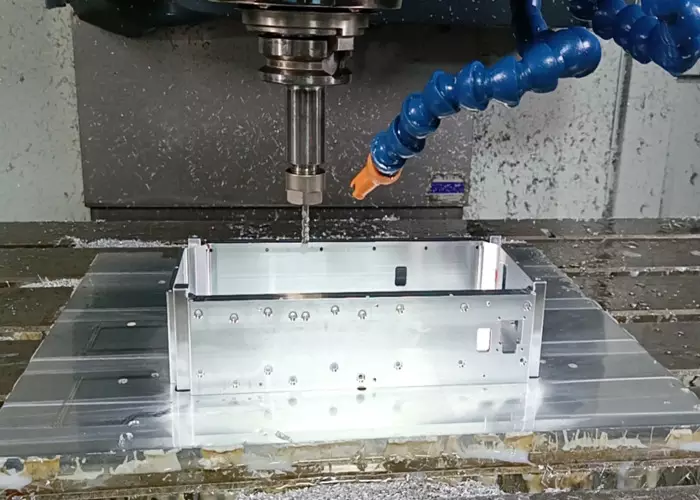

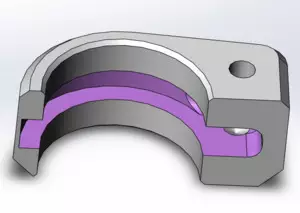

CNC Milling

- Including 3, 3+1, 3+2, 4+1, 5 axis

- Max part size: 3200*2200*1000mm

- Min dimensional tolerance: ±0.005mm

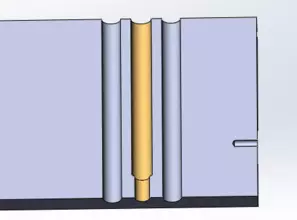

CNC Turning

- Including turning and mill-turning

- Max part size: φ600*500mm

- Min dimensional tolerance: ±0.005mm

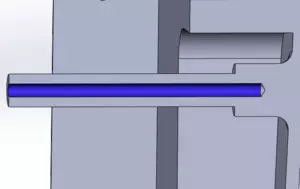

Gear Machining

- Including gear milling and hobbing

- Min concentricity: ±0.008mm

- Min dimensional tolerance: ±0.005mm

CNC Machining Case Study

From prototype to production, we control every step. Do not need to worry about the delay, photos of every step will be updated on your portal timely. You can monitor the entire production remotely. If it stops or is delayed, you will know quickly.

Buy Material

06.07.2022

Mark Chan

IQC

07.07.2022

Jenny Zhu

CAM

06.07.2022~08.07.2022

Andy Lee

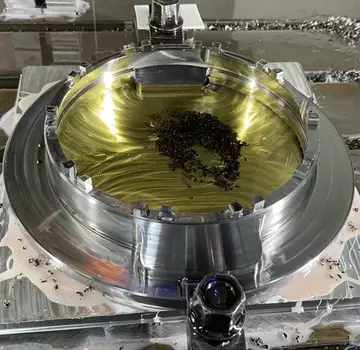

CNC Machining

09.07.2022~15.07.2022

Bruce Tang

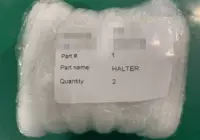

Package

19.07.2022

Kelly Huang

OQC

18.07.2022

Jenny Mong

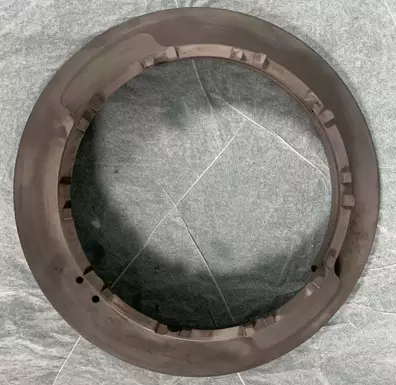

Finish

16.07.2022~17.07.2022

Henry Zhao

IPQC

09.07.2022~15.07.2022

Ben Zhang

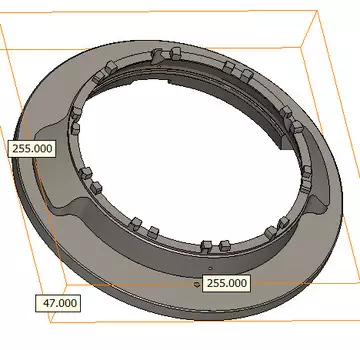

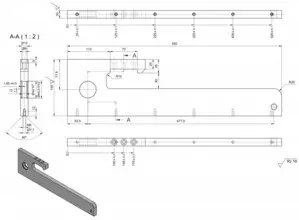

How Do We Customize Production?

We will coordinate and use different machines according to the features and quantity of parts, which can help you reduce machining time and cost. Maintain consistency in quality at every stage.

Prototype

The fast response and agile production management make the delivery time as fast as 2 days.

- NDA (Non-Disclosure Agreement)

- Talk with project engineer directly

- DFM(Design for Manufacturability) report

- Update production status with photos

- Pass rate 98.1%

- Min dimensional tolerance: ±0.005mm

Production

We optimize manufacturing plan and arrangement to shorten machining time and cost for you.

- Support online video audit

- NDA (Non-Disclosure Agreement)

- Talk with project engineer directly

- DFM(Design for Manufacturability) report

- Update production status with photos

- FAI(First Article Inspection) report

Let's Talk About Your Project

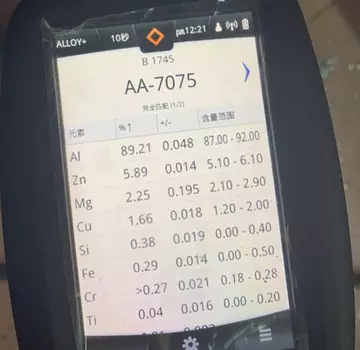

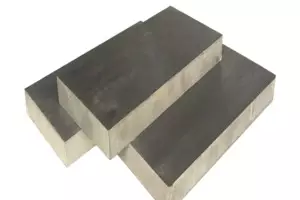

Materials for CNC Machining

Choosing the right material for your project is important. Turnkey has a wide supply chain with more than 50 plastic and metal materials for you. If you are not sure which material is the best choice, our engineering team is ready to help.

Aluminum

- 2000 Series Aluminum:AL2014, AL2017, AL2030

- 5000 Series Aluminum:AL5052, AL5754, AL5083

- 6000 Series Aluminum: AL6060, AL6061, AL6082

- 7000 Series Aluminum:AL7075

Steel

- Stainless Steel: SUS303, SUS304, SUS316

- Tool Steel: 1.2311, 1.2363, 1.2379, 1.2767

- Carbon Steel: Q235, Q275, S45C

- Alloy Steel: 4140, 4130, 4340

Plastic

POM, ABS, PC, ABS+PC, PTEF, PEEK, HDPE, PP, PA, Nylon, PMMA, PET, PEI, PPS, PVC, PE

Titanium

- TC2, TC4, TC5

- Military-grade Titanium Alloy

- Food-grade Titanium Alloy

- R53400 Titanium Alloy

Copper

Copper 101, Copper 110, Copper 122, Copper 145, Copper 172, Copper 182

Brass

H62, H65, H68, H70

Magnesium

AZ91D, AZ31B

Zinc

Zinc alloy

Finishes for CNC Machining

There are clear milling marks on the parts. If you want to beautify or protect your parts, you can choose a surface finish for your custom parts. Turnkey provides 10+ finish choices for you.

- Anodizing - natural, black, blue, red, custom colors

- Chemical blacking

- Hardening - vacuum hardening, gas nitriding, carburizing

- Electroplating - nickel, zinc, chrome

- Painting - custom colors

- Powder coating - custom colors

- Passivation

- Pickling

- Polishing - chemical polishing, electrolytic polishing

- Bead blasting

- Brushing

- Silk screening

- Laser engraving

- Nanostructured ceramic - custom colors

Our Efforts in Shipping Safety

Our professional packing standard will help you lower the risk of damaging parts during transportation.

Step One

Clean and remove oil. Use protective material on the parts individually (paper or a protective net) to ensure a spotless surface that won’t scratch in the shipping.

Step Three

Additionally, fix and protect the parts within the package with filler material.

Step Two

After the individual packaging, protect the parts with air bubble packing and wrap them with adhesive tape. Then place custom labels so that you can distinguish them.

Step Four

Print out the materials and measurement documents and place them in the box. Then close the box.

Clients' Feedback

FAQ About CNC Machining

Our team will offer free DFM as per every project and if the material you choose is not the best choice for your project, we will suggest you some materials for you to choose from.

Any crucial dimensions should be mentioned on the 2D drawings or to our project engineers directly.

CNC machining will proceed the part with one piece of raw material, so it is more suitable for structural parts.

There are few available finishes for 3D printing. You can have more options with CNC machining.

Indeed hourly price for 3-axis CNC is much lower than for 5-axis CNC. When we quote, we compare the cost of multiple machining plans and choose the best solution.

If some features are impossible to proceed with the 3-axis or other machines, we have to proceed with the 5-axis.

For turning parts, we can make them with 2D drawings. For milling parts, our engineering team can work out 3D drawings for your checking then. If the drawing is confirmed, we will proceed accordingly.

However, if the structure is kind of complex and may need 5-axis CNC to make it, prototype molding will be a better choice in this case.

Yes, we can offer design services for those companies without their own design team. However, for this issue, it will take longer communication time and once the need is fixed, we will charge you before we proceed with the drawing for you.

Before we ship out the parts, our QC team will take strict quality inspection all over and only ship them when everything is okay.

We fully understand sometimes it is hard to choose a suitable material. In this case, you can share all the details about your design with our project engineer, for example, usage, function, working conditions, and anything related, then our project engineer will come back to you with DFM and suggest you some options for you to decide.

The Secret to Reducing Sourcing Risk and Manufacturing Costs

Manufacturing parts is not our goal, our value is helping customers grow their businesses. The engineering team with 20+ years of work experience provides free DFM reports with you to help you reduce procurement risks and manufacturing costs.

Free DFM Report

- Analyze manufacturing risks

- Optimize part design

- Improve machining efficiency

- Save processing costs

- Control production quality

Materials analysis

Whether the material could be bought

Whether the material is okay to be machined by CNC

Whether the material is available for customers’ chosen surface finish

Drawing analysis

Analyze if dimensions from 2D and 3D drawings did not match

Analyze if the surface roughness can meet the requirement

Analyze whether the parts need to be assembled together

Structural analysis

Analyze if the structure of part is suitable for CNC machining

Analyze whether the wall thickness, hole, undercut, inner right angle features can be machined by CNC machining

Tolerance analysis

Whether dimensional tolerance and tolerance of form and position can meet the requirement

Whether the part will deform and influence dimensional tolerance during machining and welding

- Whether the surface finish process will influence the dimensional tolerance

CNC Parts Design Tips?

The structure of the part is the biggest factor influencing the machining cost.

Why is the cost control of your competitors more advantageous? You are just overlooking some details.

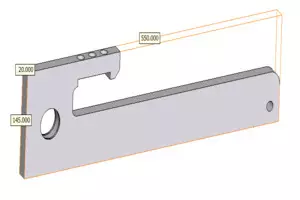

Round inner features

The cutters are round and cut off the extra material by rapid turning of the blade. In this case, there is nothing the cutter can do about right-angle features. If the right angle feature is a must, it will cost you more money on it. Changing the inner feature to be radial is the best solution to lower cost if it does not influence further assembly. Ideally, the internal fillet diameter of plastic parts is at least 1 / 9 of the cavity depth. The aluminum parts shall be at least 1 / 8, and the steel parts shall be at least 1 / 6 of the cavity depth.

Thicken thin walls

Thin walls are fragile. If the cutter moves too fast, the thin walls will be rough due to the cutter bounce. The distance between holes and edges should be enough. Ideally, the distance from the hole to the edge of the plastic part shall be at least 0.8mm, and for the metal part, it shall be at least 0.5mm.

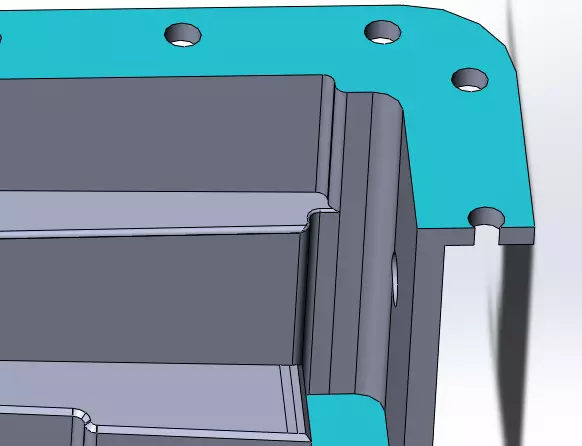

Avoid deep cavities

Deep cavities need to move away a lot of excess material which increases machining costs accordingly. Sometimes we have to make a customized cutter for the features and it will also increase the cost. Ideally, the maximum depth of cavities for plastic parts shall be 9 times the diameter of the cutter. For aluminum parts shall be 8 times while for steel parts shall be 6 times. The minimum cutter diameter is determined by the inner radial feature diameter. For example, if the inner radial feature is R1, the minimum cutter diameter which can be used is R1.

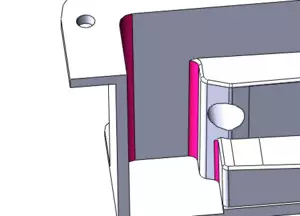

Avoid undercuts

Undercutting often requires custom cutters. The cost of cutters will be added to the machining cost as well. So, only make it when absolutely necessary.

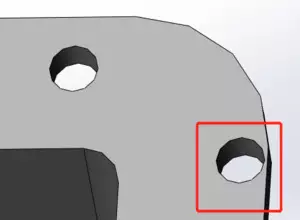

Avoid deep holes

Deep holes have high requirements on the strength of the reamer. Ideally, the maximum hole depth of plastic parts shall be 10 times the diameter of the reamer. The aluminum parts shall be 8 times, while the steel part shall be 6 times. If your design is out of scope and requires custom cutters or process change, there shall be an extra cost.

Appropriate threaded hole depth

Too long threads will not make the assembly tighter or closer. If the hole depth is greater than 3 times the hole diameter, the tap will have a break risk and we will spend more time on the deep hole. In fact, a thread depth of 1.5 times the diameter is enough to assemble the part securely.

Book a meeting with our project engineer today

If your files are out of the limit, please kindly send your files to info@besturnkey.com. Thank you.

*All uploads are secure and confidential.