Online Customized Die Casting Service

Production for Metal Parts

- Rapid Molds Available

- Tight Tolerances

- MOQ 200pcs

Precise Die Casting Services

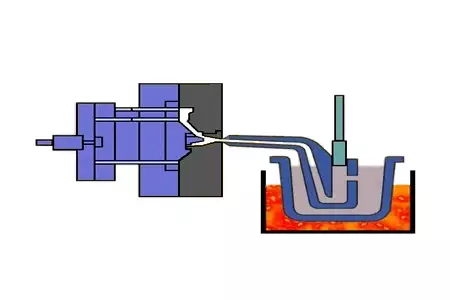

Hot-Chamber Die Casting

Also known as gooseneck machines, rely upon a pool of molten metal to feed the die. Hot-chamber die casting is fast in cycle times and convenient to melt the metal inside. But, it is limited to use with low-melting point metals. Therefore, hot-chamber machines are primarily used with zinc-, tin-, and lead-based alloys.

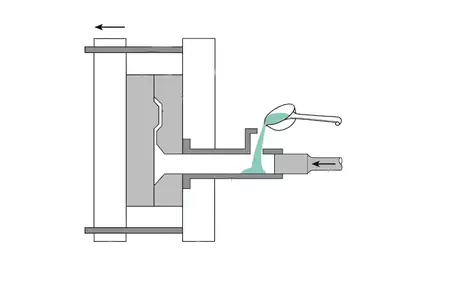

Cold-Chamber Die Casting

The metal will melt in a separate furnace before being transported to the cold-chamber machine, where it is fed into an unheated chamber. Cold-chamber die casting is more suitable for high-melting point metals but has a slower cycle time because of the transfer of molten metal.

Why Choose Us for Your Sheet Metal Project?

Intelligent Manufacturing Service

Lower risk & cost. DFM report will help you optimize design if necessary

Save communication time & cost. No need to find other partners for different processes

One-stop service. We can support “Design-> Manufacture->Assembly” one-stop delivery

Clear update. You will know every step of your project with detailed photos. No need to worry

Ensured quality. Every project will follow our strict quality control system

Traditional Manufacturing Service

High risk & cost. Without a DFM report in the early stage, problems may occur during the manufacturing

Long communication time & cost. Have to talk with several suppliers for different processes

Single service. May pay extra cost for assembly after collecting the parts from suppliers

Unclear update. You are the last one to know if any delays and have no idea about the delivery schedule

Unstable quality. No clear quality control process and may have problems if any information was not shared

What differences between Rapid & Production Molds?

Die casting rapid molds and production molds are both used in the die casting process, but they have some important differences in terms of their cost, speed, and quality.

Rapid Molds | Production Molds | |

Cost | More economical | Expensive |

Material | Less durable materials, like aluminum, epoxy | More durable material, like steel |

Time & Labor | Save time & labour | More time & labor |

Speed | Faster in design and manufacture | Need more time to design and manufacture |

Quality | Good, but have limitations in terms of dimensional accuracy, finish, and mechanical properties | Better, made from durable materials and are designed to withstand the high pressures and temperatures of die casting process |

Lifespan | Shorter | Longer |

Let's Talk About Your Project

Optional Materials for Die Casting

Die casting can be used to produce parts from a wide range of materials. The choice of material will depend on the specific requirements of the project, such as the desired properties, cost, and application of the part. Below we listed some common materials we use.

Aluminum

Lightweight material with an excellent strength-to-weight ratio, high thermal conductivity, and corrosion resistance. It is commonly used in the automotive and aerospace industries.

Zinc

A versatile material with excellent dimensional accuracy, strength, and durability. It is often used in consumer products, electrical components, and automotive industries.

Magnesium

Lightweight material with a high strength-to-weight ratio, good thermal conductivity, and superior machinability. It is commonly used in the automotive and aerospace industries.

Optional Finishes for Die Casting

The choice of finish option will depend on the specific requirements of the project, such as the desired appearance, functionality, and environmental conditions the part will be subjected to.

Painting: adds a layer of paint to the surface of the part to improve its appearance and provide corrosion resistance.

Powder coating: applies a powder coating to the surface of the part and provides a durable and corrosion-resistant finish.

Anodizing: forms a coating on the surface of the part to improve its corrosion & wear resistance, and appearance.

Polishing: removes any imperfections on the surface of the part and creates a smooth and reflective finish.

Plating: applies a metal coating to the surface of the part to improve appearance, corrosion resistance, and conductivity.

Bead blasting: uses high-pressure air or water to remove any surface impurities and create a uniform and textured finish.

How Does Die Casting Work?

Die casting is a metal casting process that uses a mold, called a die, to create complex shapes with high precision and consistency. The mold is usually machined from a stronger alloy, a process somewhat similar to injection molding. Once the metal is cooled and solidified, the die will be opened, and remove the finished part.

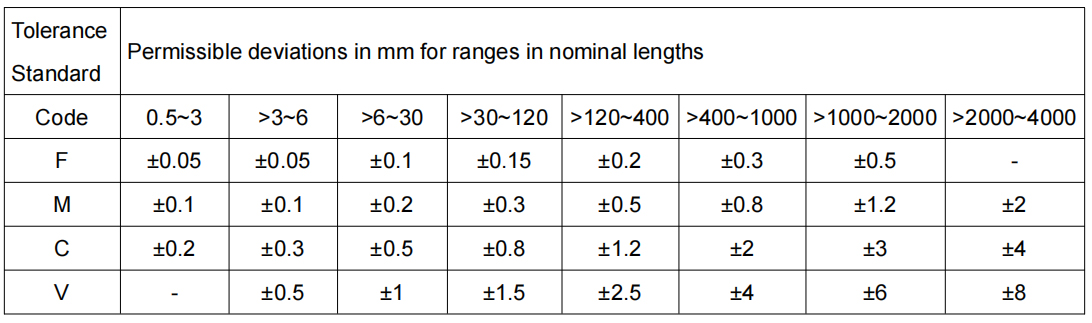

Tolerance Standards for Die Casting

The tolerance standards for die casting depend on several factors, including the complexity of the part, the size of the part, and the type of material being used. Generally, die casting tolerances are in the range of +/- 0.005 to 0.020 inches, or +/- 0.13 to 0.51 millimeters.

Client's Feedback

FAQ About Die Casting

Here we have some basic guidelines for die casting parts:

- Even wall thickness

- Rounding of all edges and corners

- Smooth blending and continuity of all the features

We will provide additional design modification suggestions to make sure your parts are casted successfully.

Yes, we can put PEM studs, nuts, fasteners, or hardware like McMaster-Carr components or inserts into the parts.

You can send us 2D and 3D drawings of the parts to us first and tell us what material, quantity, and finish you would like for the parts. Then we will quote you the price according to your requirements with a DFM report if necessary.

In Turnkey, for supporting customers better and lower expenses in the front stage, our MOQ is 200pcs for die-casting projects.

If new die is required, samples will be ready in 10 to 12 weeks. After getting approval, official parts will be sent within 12 weeks basically.

In Hot-chamber die-casting process, molten metal is injected through the cavity of a pre-shaped mold using pressure. The metal will be heated inside the casting machine rather than a separate machine or furnace.

The die casting parts can be supplied in a natural state or with secondary finishes, like, anodizing, plating, painting, and powder coating but it will depend on the material. Our team will give you further details about your project.

Sure, we can offer a scanning service and make the drawing for you. Once the drawing is confirmed, we can quote you the price for the die casting process. However, for the scanning and drawing-making process, we have our cost standard, and our project engineer will confirm with you ahead of the whole process.

Differences between Die Casting & Injection Molding

Die Casting | Injection Molding | |

Part material | Metal parts, like aluminum, zinc and magnesium | Plastic parts, like ABS, PCB and ABS+PC |

Manufacturing process | Inject molten metal into a mold under high pressure | Inject molten plastic into a mold under high pressure |

Mold material | Steel | Aluminum or steel |

Part complexity | Produce parts with more complex geometries and thinner walls | Produce simpler parts with thicker walls |

Finish | Smoother and higher quality than injection molding | Good finish and textures can be chose |

Cost | More expensive | More cost-effective |

Die Casting Project Pros & Cons

Die casting is a versatile and efficient metal casting process that has both advantages and disadvantages. Here are some of the pros and cons of die casting

Pros

High precision & accuracy

Die casting can produce complex and highly accurate parts with tight tolerances.

High production efficiency

Consistency & repeatability

Versatility

The process can be used to produce parts in a wide range of sizes and shapes, from small components to large structural parts.

Good surface finish

Die casting can produce parts with a smooth and high-quality surface finish.

Cons

High initial tooling costs

The cost of making the die mold can be high, which makes it less suitable for small-scale production runs.

Limited material selection

Die casting is best suited for materials with low melting points such as aluminum, magnesium, and zinc.

Porosity

It can result in small air pockets or voids in the material, which can affect the structural integrity and appearance of the part.

Size limitations

Limited design flexibility

The process has some limitations in terms of the complexity and design features of the part.

Book a meeting with our project engineer today

If your files are out of the limit, please kindly send your files to info@besturnkey.com. Thank you.

*All uploads are secure and confidential.